16 Dec 2024

Materials of the future: implications and developments in textiles

Beyond cotton: polyamide for a responsible textile future

The apparel industry is in the spotlight for its significant environmental impact. From fiber production to end-of-life management, each stage of a garment's lifecycle imposes a cost on the planet in terms of resource consumption, pollution and waste generation. This growing awareness, coupled with a significant shift in fashion preferences towards performance-oriented apparel, is influencing material choices. While conventional cotton remains an important fiber in the textile industry, it is being joined by polyamide fibers that, thanks to innovative and sustainable production processes, can combine style, environmental responsibility and high performance to meet the needs of an evolving marketplace that is attentive to product quality, comfort and sustainability.

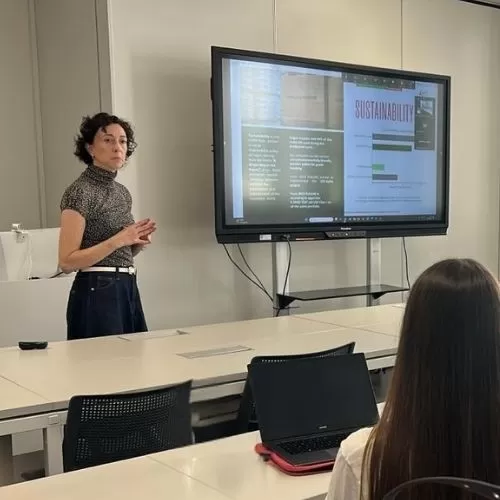

From fiber to garment: a complex journey that starts with design

The sustainability of a garment is not limited to the choice of material, but is the result of a complex journey that begins with fiber production and ends with the disposal of the product at the end of its life. As highlighted by the European Sustainable Product Policy, the environmental impact of a product is largely determined at the design stage. In fact, it is estimated that more than 80 percent of the environmental impacts associated with a product are defined at the design stage. This means that the choices designers make about materials, manufacturing processes and final product features have a huge impact on the overall environmental impact. Adopting a sustainable design approach is therefore critical to reducing a garment's environmental footprint.

Polyamide vs. conventional cotton production: debunking a myth

Life Cycle Analysis (LCA), a methodology for objectively assessing the environmental impact of a product throughout its life cycle, provides us with a valuable tool for comparing the environmental impact of producing different textile fibers and dispelling some myths. Take conventional cotton, for example, which is often perceived as the ultimate natural and sustainable fiber. However, LCA analysis reveals a more complex picture.

Environmental impacts

Conventional cotton production requires massive amounts of water: an average of 11,000 liters of water is needed to produce 1 kg of cotton, with peaks of up to 29,000 liters. This is an alarming figure given the increasing scarcity of this precious resource.

In addition, conventional cotton production involves the use of pesticides and fertilizers that pollute the environment and threaten biodiversity. Finally, the production of cotton yarn requires high energy consumption, which contributes to the emission of greenhouse gases.

In this context, the polyamide produced by Fulgar stands out for its lower environmental impact in terms of water and energy consumption. LCA studies conducted by the company have shown that the polyamide produced can offer water savings of up to 90 percent compared to cotton for the same weight of fabric. In fact, Fulgar is committed to reducing the environmental footprint of its products through the use of recycled and bio-based materials and the implementation of innovative technologies with low environmental impact.

Innovative yarns such as EVO® by Fulgar, 100% bio-based and derived from renewable sources, save up to 52% water compared to conventional cotton, while Fulgar's Q-NOVA® textile fiber, derived from a mechanical recycling system, increases water savings to 99.9%, or approximately 17,983 liters per kg of product.

In terms of CO2 emissions, Fulgar's polyamide yarns are also a more sustainable choice. Q-NOVA®, for example, has an impact of approximately 1.77 kg CO2 eq, while conventional cotton has a 60% to 80% higher impact than other fiber and yarn categories. Another concrete example is Q-CYCLE by Fulgar®, a yarn made from regenerated raw materials that significantly reduces CO2 emissions. According to analyses carried out using the European LCA method, Q-CYCLE reduces CO2 equivalent emissions by about 40% compared to a conventional Fulgar nylon yarn. This result confirms Fulgar's commitment to promoting a more sustainable textile industry without compromising the quality and performance of its products.

Comfort and performance

The benefits of Fulgar polyamide are not limited to environmental impact. In fact, this fiber offers high performance in terms of comfort and breathability, characteristics that make it ideal for a wide range of applications. Unlike cotton, which tends to retain moisture, polyamide offers excellent moisture management, keeping the skin dry and providing optimal comfort. These properties make it particularly suitable for sportswear, where breathability and the ability to wick away perspiration are critical to ensuring maximum comfort during physical activity.

Polyamide is also ideal for athleisure garments, a growing trend that combines comfort and style, and for underwear and hosiery, where lightness, softness and the ability to cling to the body without constricting are essential. Polyamide garments are strong and durable, maintaining their aesthetic and functional characteristics over time.

Towards a more responsible textile future

Thanks to technological innovation and a growing focus on sustainability, polyamide is emerging as a versatile, high-performance and increasingly eco-friendly fiber. Through more sustainable production, it can be a viable alternative to cotton, combining high performance and environmental friendliness. It is essential to continue to invest in the research and development of increasingly sustainable, high-performance polyamide yarns that meet the needs of an evolving market.

Learn more about Fulgar polyamide yarns and the company's commitment to a more sustainable textile future. Contact Fulgar!