Applications:

Properties:

Lightness

Lightness

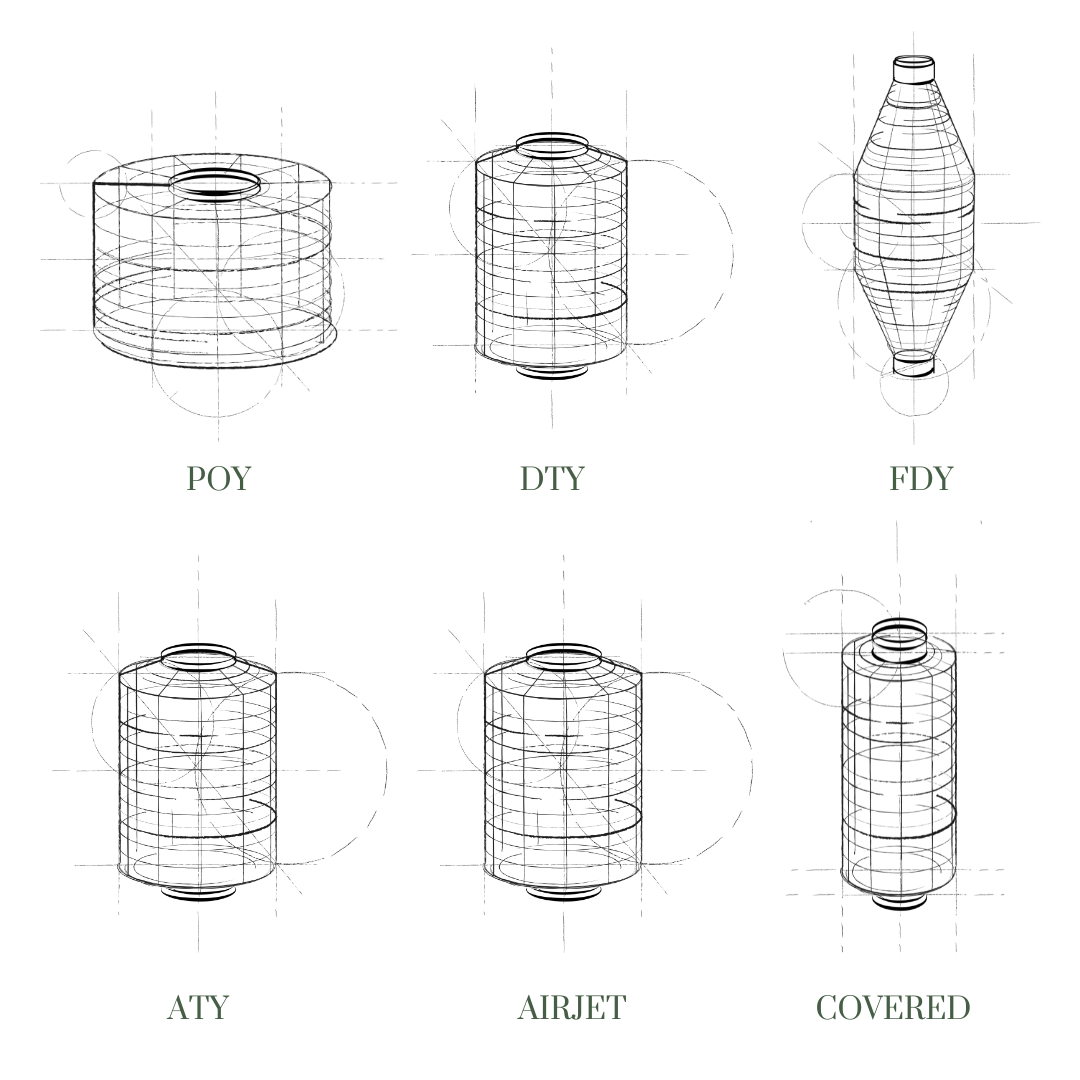

Possible processes

Polyamide 6,6 POY Yarns;

Polyamide 6,6 DTY-Drawn Textured Yarns;

Polyamide 6,6 ATY-Air Textured Yarns;

Polyamide 6,6 FDY Flat Yarns;

Polyamide 6,6 CCY-Conventional Covered Yarns;

Polyamide 6,6 AJC-Air Jet Covered Yarns.

WHAT IS Q-CYCLE?

ECOLOGICAL TEXTILE INNOVATION: THE FUTURE WITH Q-CYCLE BY FULGAR®

At the forefront of ecological textile innovation, the new Q-CYCLE yarn is the result of the interaction between BASF's ChemCycling® project and Fulgar's textile expertise and experience. ChemCycling® uses pyrolysis to replace fossil raw materials with a secondary material derived from the chemical recycling of tyres at the end of their life cycle. Using a third- party audited mass balance approach, the proportion of this recycled material is attributed to the final product, which has the same properties as the conventional grade.

The result is Q-CYCLE, an innovative polyamide 6.6 yarn in which 100% of the raw material required for its production has been replaced by pyrolysis oil from end-of-life tyres and is attributed according to a mass balance approach.

This polyamide yarn combines the functional and aesthetic advantages of lightness, strength and durability in a more sustainable version. Ideal for the production of high quality apparel fabrics, it is the perfect solution for a wide range of textile applications. It is also as easy to process as a traditional polyamide and can be seamlessly integrated with other yarns.

PROPERTIES

VERSATILITY

A yarn suitable for all types of textile applications, as easy to process as a traditional polyamide and compatible with all fibres.

BREATHABILITY

Q-CYCLE by Fulgar has excellent moisture management properties to keep the skin cool and dry.

CONSISTENT QUALITY AND PROCESSES

Fabrics and garments made with Q-CYCLE by Fulgar® retain the same strength as those made with virgin polyamide, guaranteeing continuity of dyeing and production processes without variations.

WHAT IS THE MASS BALANCE?

Mass balance is an accounting system used to calculate and balance the amount of recycled raw material used in the production of fibre, such as clothing, when recycled and virgin materials are combined in the production process. This system ensures that the amount of recycled material used at the start of the process is exactly the same as the amount attributed to the finished products sold, and is verified by independent auditors according to recognized certification schemes.

Elements of Sustainability

Sustainability is one of the main pillars of Fulgar's social responsibility policy and is well expressed by the slogan “a better way to the future”. These words sum up Fulgar's keen environmental awareness and fierce determination to preserve and enhance the global ecosystem.

Discover more